An ultra-compact, lightweight, high-performance spring drill ideal for rock bolt construction and slope construction in high and narrow places. The rotational force of the hydraulic motor generates the rotation of the two blade-shape camshafts, pushing the related hammer backwards.

Two springs, one large and one small, are housed inside the hammer. Since the springs are pushed down in the direction of compression, they are released from the camshaft at a predetermined position, and at the same time, the striking energy is generated by the hammer's own weight and the reaction force of the spring compression.

The generated impact energy is transmitted to the bit at the tip through the rod, and able to drill the target such as bedrock.

- Before

- After

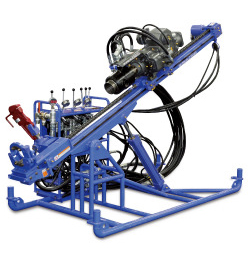

Anchoring work

- Before

- After

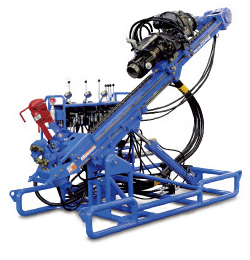

Water removal work

・Thanks to the high output, it is possible to drill speedily into gravel layers and bedrocks and shorten the construction period.

・Our drifter can do many kind of works such anchoring for the purpose of preventing collapses and landslides, contributing actively to a sustainable development.

・The newly developed high power drifter (patented) generated by springs, performs 5 to 10 times the impact efficiency of conventional products.

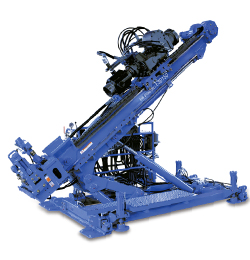

・Newly developed low horsepower drifter is a compact, lightweight machine.

・The number of parts is very little, the structure is simple, the maintenance is easy.

- Conventional technology

- High impact force and high horsepower

- Not compact

- Structure is complicated

- Many components

- Maintenance difficult

- New technology

- High impact force and low horsepower

- Compact and light

- Structure is easy

- Few components

- Maintenance easy